DYNAMIC ROUTING: NEXT-GENERATION FIELD INTELLIGENCE

DYNAMIC ROUTING: NEXT-GENERATION FIELD INTELLIGENCE

The days when oil and gas operators could afford to send their pumpers to every well every day for a checkup are long gone. Unfortunately, some operators either haven’t realized this or are simply too set in their ways to change. Instead of taking advantage of evolved solutions, they persist in maintaining the same outdated routines. This strategy is not sustainable. Now is the time for next-generation field intelligence.

Leading operators define field strategies that are operationally mature while continuing to allow the business to be agile and cost-effective. They empower their lease operators for maximum utility in cash conscious environments. They push their field into tighter alignment with business objectives. They do this with a technique called dynamic routing powered by field data gathering (FDG) software that harnesses that boosts your operational efficiency.

HOW DYNAMIC REPORTING WORKS AND WHY IT’S IMPORTANT

Dynamic routing is the process of organizing your company’s field activities on the basis of efficiency, for instance sending your company’s pumpers to wells based on their servicing needs, rather than using a strictly location-based approach. The process is facilitated by advanced artificial intelligence (AI) algorithms that use cascading logic to prioritize well visits for optimal impact, saving you both time and money.

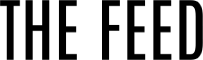

These algorithms are created by field data capture software, such as Seven Lakes’ JOYN FDG, which uses field intelligence to come up with recommendations aimed at enabling you to optimize your field activities. These recommendations can be used in conjunction with the Management by Exception methodology, which emphasizes prioritizing business activities that can be optimized or that are experiencing issues. The enhanced efficiency enabled by combining cutting edge software and best practices industry management methodology can substantially improve productivity.

DYNAMIC ROUTING IN ACTION

To understand how dynamic routing can powerfully impact a producer’s well servicing expenses, consider the following scenario: A producer has a 20-well route in which 6 of the wells require service as they are pumping below capacity. Servicing the route strictly based on location proximity to the pumper would result in visits to properly functioning wells prior to those that need service. Furthermore, of the 6 wells in need of service, 2 are significant producers while the other 4 are minor producers.

Dynamic routing algorithms takes these factors into account and route your pumper to service these wells in the most efficient pattern. Wells that need servicing are given priority over those that don’t, and wells that produce significant volumes of oil or gas are given priority over those that produce smaller amounts. In the above scenario, the software’s AI algorithms would select the route that enabled your pumper to most efficiently bring the poorly performing wells back to acceptable production levels, taking into account their production capacity and geographic locations.

OPTIMIZING FIELD ACTIVITY WITH DYNAMIC ROUTING

Using this approach to replace the traditional process of visiting wells on a regular basis, whether or not servicing is required, enables your company to take advantage of the information revolution sweeping through the oil and gas patch. Field intelligence gathered from SCADA and other sources provides the raw material applications such as JOYN need to optimize your routing operations. FDG software enables you to optimize your existing technology investments by putting the information it generates to productive use.

While dynamic routing can save an operator money even when dealing with a fairly small number of wells, its benefits ramp up dramatically as a producer expands the scope of its activities. In a Seven Lakes’ whitepaper on the benefits producers can derive from using field intelligence tools, the director of information technology of a major Williston Basin producer, speaking of the difficulty of servicing wells efficiently at scale, said: “That (traditional routing) doesn’t scale without headcount. If I have a hundred wells that’s fine. If I have a thousand wells it’s not so fine. If I get ten thousand wells, then holy cow what do I do.”

Dynamic routing is at the heart of the information revolution currently disrupting the oil and gas patch with next-generation dynamic routing. Can your company afford to continue using inefficient legacy processes while your competitors ramp up their productivity (and production) using the process?

ACHIEVE WORK ORDER AUTOMATION IN A COMPLEX OIL FIELD

With big data and automation rationalizing operational processes in industry after industry, why do so many oil and gas producers still rely on antiquated systems and centralized processing to produce work orders? There are a number of reasons these legacy processes persist, even when more efficient solutions exist: sunk investment in legacy systems, organizational inertia; resistance to change; centralized operational systems.

None of these reasons alters the reality that using field intelligence software to optimize work order delivery and completion substantially enhances a producer’s operational efficiency. By empowering your field personnel to complete work orders on-site through a field data gathering (FDG) tool you will save significant time and money. Achieve work order automation to streamline field operations.

UNIFIED SYSTEMS IMPROVE WORK ORDER EFFICIENCY

When pumpers encounter difficulties with a well, the traditional method for creating work orders was to use a paper process or to return to the office, whether at work or at home, to fill out a form and send it to company headquarters. Often the process involved printing out a form to complete, and it typically took place on a separate system from the one used to compile or manage field operations.

Using JOYN FDG to complete and process work orders adds significant efficiency to work order completion. Instead of needing to return to an office to prepare and send a work order, pumpers can now do so right from their laptop or other portable device in the field. They also benefit from being able to use the same platform that provides dynamic routing and other field optimization functions. Now, instead of having to toggle back and forth between separate systems to gather and report data, they can do it from a unified FDG solution, minimizing the chance for errors in the process while at the same time speeding it up.

EMBRACING INNOVATION WITH OIL & GAS PRODUCTION SOFTWARE

Far-sighted producers have already adopted FDG solutions to efficiently prioritize well routing for their pumpers, helping them increase both productivity and production. As operators continue to embrace the AI and automation revolution now sweeping the oil and gas patch their ability to do more with less is creating remarkable production results. A major Bakken producer featured in Seven Lakes’ white paper on automation in the energy industry explains the journey to achieve work order automation. The key being that the solution is flexible and easily accessible for the users. They no longer have to rely on legacy procedures that can slow down field operations.

Work order automation is no longer an idea of the future but a reality for leading operators. Don’t fall behind, invest in modern field data gathering solutions.