WHAT DO YOU GAIN BY SAVING 2.5 HOURS PER DAY WITH JOYN FSM?

Your field gets two and a half hours back every day, for every worker, when they pump by exception with JOYN FSM. But what does it translate to?

Our customers tell us that the time they earn can feedback to keep high-value assets producing at peak. Field technicians and lease operators save drive time, increase well time and are proactive to avert downtime. And in addition, they have enough time in hand to deliver more tasks per day.

In fact, with JOYN platform, the largest supermajor reduced production decline from 12% to 3% in one of its oilfields.

HOW DOES JOYN FSM SAVE TWO AND A HALF HOURS FOR EVERY FIELD WORKER?

JOYN FSM brings together mobility, collaborative task management and seamless integration of oil and gas systems, equipping everyone to pump by exception. How does it all add up to optimize your fields, to pump more oil? Let’s dig deeper and explore.

Mobile data capture and validation saves every lease operator, more than one and half hours per day.

You move away from grease sheets and multiple interfaces. Run Ticket image capture, for instance, saves 10 minutes per day as artificial intelligence gathers data from the image and syncs it to the cloud instantly.

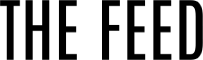

Collaborative task management equips every field worker to deliver more and save an hour per day.

Every field activity is a task. Every task is assigned a priority score. And every task is matched to the most suited resource, based on their skills, availability and proximity to the event. Now your field worker are dynamically routed to address high-value assets first. They drive to the task directly, slashing behind-the-wheel time by half an hour per day, or more.

A leading oil and gas producer in Permian brought down drive time for its field technicians and lease operators by an hour – average drive time is now reduced from 4 hours to 3 hours

Field technicians no more chase wi-fi spots and shuffle back and forth on phone calls. They access and update work orders and inventories on their mobile. They can now create tasks and communicate with their colleagues in the field and office on the go. This ensures easy collaboration between field and office. And, when lease operators, technicians and planners/ foremen are on the same page, another half hour is easily saved.

Seamless integration with SCADA, ERP, Asset Management, Production Accounting and other oil and gas systems on JOYN platform removes redundancies and delays.

Chemical injection rates are now calculated on a click. Water tickets from transporters integrated directly with vendor API. Well problems identified at the press of a button. Automated well tests are reviewed and approved at well head. And EH&S compliance forms filled on the app. Now, everything is in one place.

The largest supermajor saves more than one thousand hours every month in one of its oilfields with automated well tests and saves another 300 hours with water ticket integration.

Thus, JOYN FSM saves at least two and a half hours per day for each field worker. And, when you have 200 field workers, including technicians, mechanics and lease operators, you save

- 500 hours per day

- 2,500 hours per week

- 120,000 hours per year

With such huge time saving, your field workers can:

- Squeeze in those extra tasks.

- Make time for preventive maintenance.

- Reduce down time.

What will you do with the extra time gained with JOYN FSM? We will be waiting to know…