OILFIELD DIARIES: WHY YOU MUST CALCULATE ROI/ TCO ONLY AFTER A PUMP BY EXCEPTION PILOT

Pump by Exception is a unique journey in operational excellence for every oilfield, considering existing levels of automation, data maturity, systems integration needs, availability, skills of field personnel and other critical factors.

I was in the Permian last week, helping a midmajor start off their Pump by Exception journey with a pilot in one of their oilfields. I ride along with the lease operators to help them gain confidence in the technology., There is no better way to get the sense of the field than by being there. Any decision on what the field needs, how well it can adopt or adapt to technology must be made keeping the field in focus. Technology roadmaps, cost of ownership and return on investments will be misleading if they do not begin from the field.

CONSIDER CONTEXTUAL EXPENSES IN TCO FOR PUMP BY EXCEPTION TECHNOLOGY INVESTMENTS

Every technology investment requires a total cost of ownership (TCO) and return on investment (ROI) analysis. Oil and gas companies must weigh in the TCO and ROI required in their Pump by Exception journey to gain sponsorship. There is a catch. These cannot be theoretical or intellectual discussions in boardrooms or air-conditioned offices, away from sweat and toil of the field. Pump by Exception is a field enablement exercise and its cost or impact can only be determined in the field.

The investment on Pump by Exception goes beyond the subscription fee for the technology. There are many contextual and company-specific expenses to be accounted for, such as cost of iPhones, upgrading bandwidth, leasing maps into ArcGIS, gap automation equipment to capture production for non-automated wells, etc. And these expenses will vary from field to field, from one company to another. A standard TCO description will only be misleading.

RUN A PILOT FOR A CLEAR ESTIMATION OF INVESTMENTS AND RETURNS

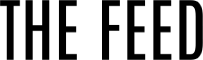

In the past three years, we have partnered with the largest supermajor, midmajor, and several other oil and gas leaders to navigate through their Pump by Exception journeys. The best way to understand the TCO and calculate ROI is to run a pilot and get real insight. Any TCO/ROI discussion ahead of the pilot is filled with guesstimates and assumptions that do not hold ground in the long run for any strategic decisions.

You must insist on a pilot to get the sense of the field and build a clear understanding of cost, effort, and impact. Otherwise, you run the risk of missing out on the input most needed – field practical experience. JOYN customers have used the pilot to:

- get the conversation out of the office and into the field, moving from theory to practice;

- experience the gap from the field’s perspective in a piloted environment;

- get the buy-in and thoughts of the field personnel who will need to adapt to and thrive with new technologies;

- determine the starting point of their journey and piece together the minimal requirements to deliver success on a long term strategy;

BUILD A PHASED APPROACH FOR A SUCCESSFUL PUMP BY EXCEPTION JOURNEY

Successful pilots have made JOYN customers determine their Pump by Exception roadmap with ease. Being in the field helped them:

- decide which variables to consider and calculate for long term success

- determine a phased approach, considering existing levels of automation, data maturity, systems integration needs, availability, skills of field personnel and other critical factors

- understand and calculate different types of investments needed to see success in phases

What is your process to determine technology investments? Is It better to keep it an academic discussion or get your hands dirty by getting a sense of the field?

I will be waiting to hear from you.