FIELD DATA CAPTURE – THE VALUE OF MOBILITY

Production Field Data capture – how E&P companies gather information about how much Oil & Gas they produce and sell, is a key factor in evaluating an Oil & Gas company in the Financial markets. Although a lot of advances have been done and are going on in the Drilling & Completions area, the methodology and processes for Oil and Gas Field Data Gathering haven’t changed much in decades.

- Lease Operators (also called Pumpers) A majority of Oil Production related field data capture in small to mid-size and even in many large E&P companies is done utilizing a group of pumpers. A pumper’s daily job is to drive around to different well leases on the route he is assigned and record readings on various meters, tanks and equipment installed on the location. He typically writes the readings on a piece of paper called grease sheet and (or) also enter the data into a Field Data Production software on a computer or handheld device (e.g. Toughbook, tablet). At the end of the day, he goes back to the field office or his home and syncs his readings to the central server.

- SCADA Systems Another common way in which companies collect field data is through automated SCADA systems and controls. These systems usually are expensive with upfront costs ranging $40K – $60K per well. Most mid-size to large independent E&P companies will have 0-20% of wells connected via SCADA. But even with SCADA systems in place, pumpers are needed to visit the wells every day to make sure that the SCADA reading is correct. You wouldn’t know that while monitoring it from the office.

There are many problems with the above two approaches:

- SCADA systems are way too expensive to build and maintain. Even with the SCADA system you need human intervention to make sure that SCADA is correct. The cost prohibits company-wide adoption of SCADA systems.

- Production information reaches Operations and Corporate Office after a delay of 1-2 days because pumpers sync their readings only at the end of the Day and then the Production Allocations have to run only after that the Managers and field staff can look at the numbers

- Existing Field Data gathering systems are not flexible enough to handle changing Business needs on field data capture

- There is also an emotional factor to this. Till the time the pumper doesn’t have all his readings synced he can’t call it a day. He is constantly under stress to get the readings in. Production staff is always after pumpers

- Some of the field data capture solutions have “per well” monthly pricing model which becomes financially prohibitive when a company is growing.

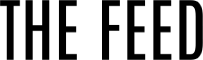

With the advent of tablets such as iPads and the additional features such as GPS, Camera, Push Notifications that they bring along, it opens a whole new platform that can bring phenomenal changes on the Oil field for these pumpers. It makes complete sense for an E&P company to embark upon Mobile Field Data Capture for the following reasons:

- Touch interface provides a very easy and intuitive platform for pumpers to enter readings

- With 4G LTE connectivity the pumper can sync his readings on the go anywhere anytime. This allows for near real-time operations and analytics for the corporate office. All of us know that the faster the information gets to the managers, the faster decisions they will be able to take and improve their company’s bottom line

- Pumpers’ stress factors go down as they are able to sync the readings more frequently and don’t have to handle rush calls all the time from the office

- It is a much more financially viable model

- With GPS tracking you have more visibility into operations and pumpers’ accountability. This provides a powerful tool in the hands of supervisors to take quick actions on the field

- Mobile devices also provide an excellent enterprise platform for the field. Most of the other business operational apps such email, messenger (Lync), timesheets etc are now available on mobile devices. A mobile device can act as a single source for all applications that the field pumper needs to use

The time is now for an iPad to be in every pumper’s hand. To learn more, visit www.SevenLakes.com.