SHIVA’S INTERVIEW PART 2: “CHOOSE BUILT-FOR-OILFIELD PLATFORM FOR QUICKER TIME TO VALUE”

Upstream E&P producers are raring to grow and training their eyes on vast terrain of oil-rich Permian basin. Growth, in the digital age must be aided by technology. And, oil and gas majors are rightly focused on getting best of the breed technologies for their field. However, many have been trying for years to build custom applications and systems inhouse. Success, though, has been elusive. Spending millions on custom software is an over stretch – on capital, resources and effort. Oilfields must focus on pumping more oil, anything else is a diversion.

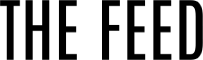

In the first part of my conversation with Shiva Rajagopal, CEO, Seven Lakes Technologies we discussed how empathy for the voice of the field can lead to pump by exception, to higher productivity. Here is this concluding part, he discusses how a supermajor, the largest oil, and gas company in the world, chose JOYN, the first built for oilfield platform, and gained quick benefits. Read on for all this and more …

QUESTION: WHY HOMEGROWN IT SOLUTIONS FALL SHORT IN MEETING OILFIELD NEEDS?

Shiva: In my conversations with IT leaders at oil and gas companies, I have been repeatedly told – “we do not want to run software shop… it has just become a necessary evil”. And, it is true. Software development is not their core. They can always try to build solutions internally, but it just takes a lot more time to realize the value and the investment continues. Another issue with a homegrown solution is that it is neither scalable, nor re-deployable or repeatable. When you try to deploy the software to new areas, it fails, because every area is different with its unique nuances. The inhouse solution can never be a software or a product that works like a traditional software that delivers value quickly. The IT teams are largely custom developing solution for specific issues as they go along and, not a platform that can scale or connect various systems.

Further, if you as a company start thinking about infrastructure servers and worry about hiring iOS developers, Data Scientists and Architects – it just becomes very complex. The project never kicks off and you may never get the funding or time to do all of this.

Instead, IT teams are better off with solutions that are built grounds up, built for oilfield, with a deep understanding of the complexities and leveraging the best practices developed with experience.

QUESTION: HOW WOULD YOU COMPARE LARGE ENTERPRISE HORIZONTAL SOLUTIONS TO A ‘BUILT FOR OILFIELD’ PLATFORM LIKE JOYN?

Shiva: It is a very simple concept – if you know the industry, you can build a solution that can be made usable quickly. However, if you don’t know the industry and if you have an open platform that you can standardize, or configure or customize to your needs it may eventually work out but at the cost of huge time and effort, and then too, you may end up adding more complexity to solve simple everyday issues. Typically, as we have seen, these large deployments have not worked out in the past because they cost more and have not yielded convincing results, soon enough. They generally drag along and therefore the projects lose steam and eventually get out of favour. You need to pick a platform that is designed for oil and gas to realize the value sooner.

A supermajor, the largest publicly traded oil and gas company in the world realized that with cyclical oil prices, they’ve got to work smarter and faster. And, therefore a platform like JOYN, that inducts new technology is critical – saving their operators, two hours a day, increasing production by few percent, and proving potential to gain over a 100 million dollars in business value. Choosing the right platform was important to gain the right value, in time. And, a lot of the other companies are thinking very similarly now. They know if they do not choose wisely, they will be left behind.

QUESTION: CAPITAL AND TIME INTENSIVE DEPLOYMENTS OF LARGE ENTERPRISE SOFTWARE OFTEN RUN OUT OF STEAM MIDWAY OR FAIL TO DELIVER DESIRED RESULTS. SHOULD COMPANIES DEMAND PROOF OF SUCCESS IN THE FORM OF POC BEFORE ACTUAL DEPLOYMENTS?

Shiva: The POC concept is useful if you have some unique requirements. Frankly speaking, even the big horizontal software providers can partner with the system integrators and do a POC. Obviously, those POCs will cost the operators and arm and a leg! However, the advantage with JOYN is that it can prove that as the cloud-based platform it is able to talk to some of their legacy systems, like the systems that are running at Exon and other companies. Integration is critical for value delivery and JOYN has connectors that connect and transfer data back and forth between the cloud and their legacy infrastructure, in-house. We’re able to develop and deploy these interfaces at a much rapid pace in comparison to some of the horizontal players. The value is seen quickly and then we move to larger deployment. The time to value is so much more important right now with low oil prices, companies would rather get the deployment happening as soon as possible and bypass delays.

QUESTION: WHAT WILL DRIVE THE VISION OF CONNECTED OILFIELD TO REALITY IN NEAR FUTURE?

Shiva: Definitely, some of the legacy thinking needs to go away. Oil prices are low. This is the most opportune moment. You just have to change. If you don’t change your mindset you’ll be left behind. Next, being open to listening to how others are improving their productivity with new technology is also important.

In other Industries AI Cloud Big Data Mobility, these are all normal things now. The Oil and gas sector is catching up. It’s happening faster now. Mobility is becoming mainstream. Everybody knows how to use apps and therefore they are easily able to make that transition from traditional software. Cloud is also becoming more and more natural with many companies, the supermajors are moving to Cloud. AI, though, has not caught on significantly, but it’s catching on slowly, but surely. And this paves the way for the connected oilfield. To me, connected oilfield literally means, my engineers should see the same information as my field workers and operators and foreman. JOYN is one platform that makes it possible.

**

Thanks for reading. You might want to check out the JOYN FSM platform by clicking here.

If you have any questions regarding how we are supporting the biggest names in the Oil & Gas industry pump by exception, feel free to drop us a note here.